GHL Doser 2.1 Slave, 4 pumps, white, Schuko

€475,00

The GHL Doser 2.1 Slave needs to be controlled via a ProfiLux Controller or a GHL Doser 2.1 Stand Alone (with integrated control electronics).

Out of stock

GHL Doser 2.1 Slave, 4 pumps precision dosing pumps

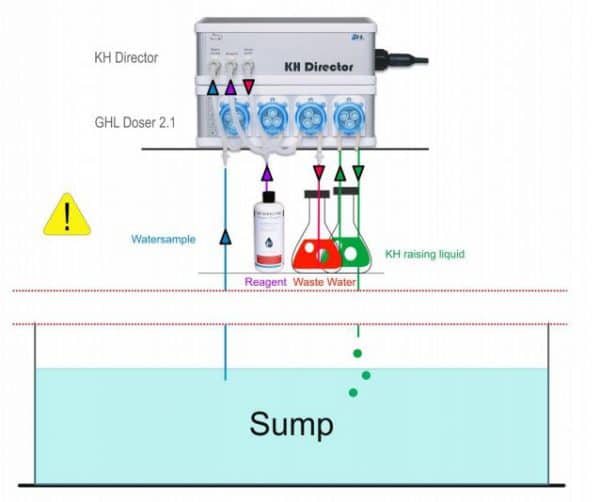

The GHL Doser 2.1 Slave requires control via a ProfiLux Controller or a GHL Doser 2.1 Stand Alone (which includes integrated control electronics). The 24V stepper motors provide accurate dosing even at very small flow rates (0.1 ml). You can connect it through WiFi, LAN, or USB.

This system can be expanded to accommodate a total of 16 pumps:

- Stand Alone + 3 Slave Doser

- ProfiLux Controller + 4 Slave Doser

The ProfiLux Aquatic Bus ensures reliable and interference-free data transfer, even at distances of up to 100 m (300 ft.).

Technical specifications:

- Color: WHITE

- Dimensions: 220 x 150 x 75 mm (without pumps)

- Variants: 4 pumps

Scope of Delivery:

- Dosing pump unit Slave (black)

- Power supply unit

With milliliter precision, this unit automates the dispensing of various liquids such as:

- Fertilizers

- Trace Elements

- Balling Salts

- Lime Water

- Liquid Feed

- Integrated evaporated water refill (Auto Top-Off)

- Water exchange of small water volumes

Additionally, it features:

- Stainless steel motor shafts (suitable for iodine dosing)

- Chemical-resistant tubing (Norprene)

- Manual operation of each individual pump

- Retrofittable pumps

- Replaceable individual parts (tubes, pump head, motor)

- 24V stepper motors allow micro doses of 0.1 ml

- Up to 150 doses per day

- Easy selection of dosing times via software (GHL Control Center)

- Automatically distributes up to 150 individual doses per day

- Individually set up to 8 doses per day

- Each pump can be configured separately

Conveying capacity and dosing:

8-45 ml/minute (precisely adjustable to 0.1 ml)

The Doser 2.1 pumps are largely maintenance-free. For optimal performance, we recommend periodically cleaning and removing dust and other impurities from the inside of the pumps. It is important that the pumps are never lubricated in any way!

Tubes, pumps, and motors are wear parts, and their lifespan depends on usage frequency, flow quantity, and environmental conditions. If you encounter malfunctions (such as insufficient flow, losing prime, leaks, or increased operational noise) or mechanical damages, the wear parts will need to be replaced. Thanks to the maintenance-friendly design, all wear parts can be easily replaced, and they are available as accessories.

| Weight | 2,0000 kg |

|---|---|

| Show MyParcel options |